.

A Brief History of EcoPak in Bike Bags

EcoPak fabric was developed as part of an initiative to create more sustainable outdoor gear materials, responding to growing environmental concerns in the textile industry. The fabric is made from recycled plastic bottles, transformed into ultra-high-molecular-weight polyethylene (UHMWPE), which is then woven into high-performance, durable fabric. This innovation not only reduces waste by repurposing plastic but also decreases the environmental footprint compared to traditional petroleum-based textiles. Since its introduction, EcoPak has gained popularity in the outdoor gear market, especially among brands and consumers looking to balance functionality with environmental responsibility.

- Early 2010s: EcoPak technology is developed, focusing on creating a sustainable, high-performance fabric from recycled plastics, primarily aimed at reducing the environmental impact of outdoor gear.

- Mid-2010s: EcoPak is introduced to the market. Early adopters are primarily premium outdoor gear manufacturers who are pioneers in sustainability. The fabric begins to gain a foothold due to its durability and eco-friendly credentials.

- Late 2010s: As awareness of environmental issues grows, more outdoor and cycling gear manufacturers start incorporating EcoPak into their product lines. Bike bags made from EcoPak become popular among eco-conscious cyclists.

- Early 2020s: EcoPak becomes a well-known material in the cycling community for its robust performance and sustainability. Several leading bike bag manufacturers now offer lines exclusively using EcoPak fabric.

Bike Bag Friendly Properties of EcoPak

Ecopak fabrics are made from recycled materials, primarily plastic bottles and other post-consumer waste, making them an environmentally friendly choice for bicycle bags.

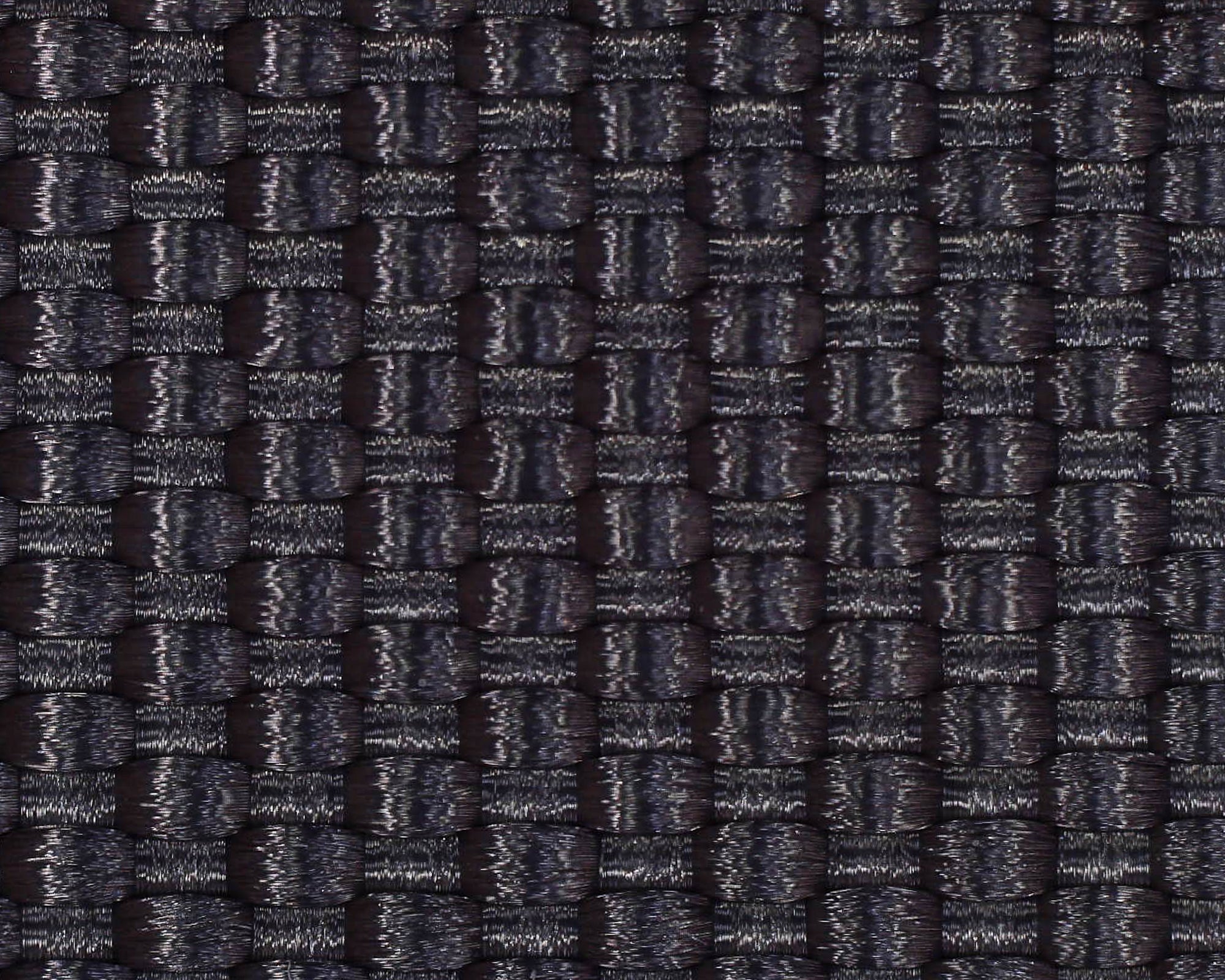

- Durability: Ecopak fabrics are designed to be highly durable and resistant to abrasion and wear. The tightly woven structure of the recycled fibers provides excellent tear and tensile strength, making them suitable for carrying heavy loads and withstanding the rigors of everyday use.

- Structure: Ecopak fabrics are available in various weave patterns, including plain, twill, and ripstop. The ripstop variety features a reinforced grid pattern that helps prevent tears from spreading, adding to the overall durability of the fabric. The structure of Ecopak fabrics allows for a good balance of strength and flexibility.

- Water Resistance: Most Ecopak fabrics are treated with a water-repellent coating, providing decent water resistance and protection against light rain or splashes. However, for prolonged exposure to heavy rain or submersion, additional waterproofing measures may be necessary, such as the use of a waterproof lining or a separate rain cover.

- Environmental Resistance: Ecopak fabrics are designed to withstand outdoor conditions and are resistant to UV rays, mildew, and other environmental factors. They are well-suited for use in bicycle bags, which are often exposed to varying weather conditions and sunlight.

- Maintenance: Ecopak fabrics are generally low-maintenance and can be easily cleaned with mild soap and water. They are also resistant to stains and odors, making them ideal for carrying gear and equipment.

- Weight: Ecopak fabrics are lightweight compared to traditional materials like canvas or cotton, making them a good choice for bicycle bags where weight is a consideration. The lightweight nature of these fabrics helps reduce the overall weight of the bag, making it more comfortable to carry or mount on a bicycle.

- Cost: Ecopak fabrics are typically more affordable than virgin synthetic fabrics or high-end technical fabrics used in outdoor gear. The use of recycled materials helps reduce manufacturing costs, making Ecopak fabrics a cost-effective option for bicycle bags while still providing good performance and durability.

Types of EcoPak & Their Usage in Bicycle Bags

- .